Last updated on January 2, 2026

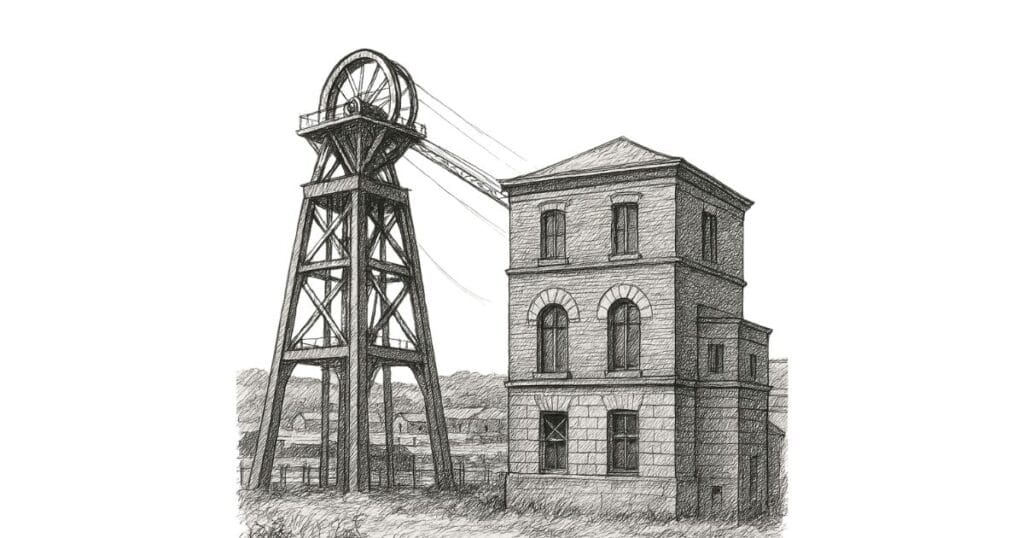

What happens in the winding house of a mine is something most people never notice at first glance. Many people are curious about what happens in the winding house of a mine because it controls every lift that connects the surface to the deep underground. When you visit a mining site, your eyes usually go to the tall headgear or the sound of heavy drills.

That tall structure is known as the head frame, and it plays a major role in guiding the hoist cable during lifting. You can learn more about what the head frame does in a mine in our detailed article.

The winding house works closely with the head frame above it. While one provides the power, the other guides the cable and keeps it steady through the shaft. Together, they make sure each lift runs smoothly from start to finish.

Table of Contents

What Is the Winding House and Why Is It Important?

So, the winding house… it is basically the part of the mine that runs the lifting. For example, if you have people or rocks that need to be transported up or down the shaft, this is where that is handled. The cage, or the skip, whatever is being used, moves because of the machine in that room. You cannot do anything underground without it working right.

Inside, you have this big drum that turns when the engine runs. Wrapped around that drum is a steel cable – strong stuff – and it pulls the cage. The winder, that is the person who runs it. They wait for a bell or a signal from below.

Then they move the cage. However, you need to be meticulous during the process. The reason being, the cage needs to stop at the apt level. Additionally, it must move smoothly, without jerking or being too quick.

These winding houses operate continuously, especially the gold mines in places like South Africa, even at night time. They move tons of rock. The system must be checked regularly, as any issue here can compromise the entire shaft.

To truly understand what happens in the winding house of a mine, it helps to see how every part moves in sync during daily operations.

What Happens Inside the Winding House During Operation

When the winding house starts running, everything inside moves with careful coordination. The operator, the winding engine, and the cables all work together to lift or lower the cage safely through the mine shaft. Every part has a specific role, and a small mistake here could stop the entire mining process.

The bell rings from the shaft

This signal tells the winder what action is needed, whether to lift or lower the cage. Each bell has a specific meaning.

The motor starts turning the drum

The hoisting engine, powered by electricity or steam, drives the large drum to begin movement.

The cable moves with the drum

As the drum spins, a thick steel cable either winds up or unwinds, making the cage rise or descend in the shaft.

The brake system manages the speed

Brakes keep the cage under control. They stop it exactly at the correct level and prevent it from moving too fast.

The dial shows depth and direction

A mechanical indicator helps the winder track where the cage is and whether it is going up or down.

Every lift, pause, and stop is carefully timed. Even a small mistake can cause a jam or accident, which is why trained winders follow strict operating procedures to prevent such incidents.

What Does a Counterweight Do for a Mine Winding System?

A counterweight in a mine winding system helps balance the load on the hoist, reducing the amount of power needed to lift or lower the cage or skip. In simple terms, it acts like a partner that shares the effort.

When the cage goes down, the counterweight goes up, and vice versa. This balance lowers mechanical strain on the winding engine, keeps movements smoother, and prevents sudden jerks that can damage the cables.

In deep mines, counterweights also reduce energy consumption because the motor does not have to lift the full load each time. They improve safety by maintaining tension in the winding rope and ensuring even braking pressure.

Key functions of a counterweight:

- Reduces power usage by balancing load weight.

- Minimises wear on ropes, brakes, and drums.

- Keeps the hoist motion smooth and steady.

- Adds safety and stability during winding operations.

What Are the Main Parts Found in the Winding House?

Here are the main parts found in the winding house. Each one helps the hoist system run safely and smoothly, allowing miners and materials to move up and down the shaft with precision.

Winding drum

This part here is a big metal drum. The cable wraps around it. When it spins, it pulls the cage up or lets it down. That’s the basic job.

Motor or engine

You need something to turn that drum, right? That’s what the motor does. Some mines use electric ones, and older ones use steam. It’s the power behind the whole setup.

Brakes

These help stop the cage when it gets to the right level. Also stops it from going too fast. Without the brakes, it would be risky.

Control panel

This is where the winder sits. You have got switches, a lever maybe, and that’s how they control what the drum does. It has to respond quickly.

Depth dial

There is this dial or gauge that tells the winder how far down the cage has gone. Or if it’s going up. They keep checking that during every lift.

Signal system

The workers underground send signals, typically a bell, to inform the winder of their needs, such as when to move the cage or stop it.

Together, these parts ensure smooth coordination with the head frame, which carries the pulleys above the shaft. Each machine and control panel plays a role in what happens in the winding house of a mine, keeping every lift steady and safe.

How the Winding House and Head Frame Work Together

What happens in the winding house of a mine is closely linked to the head frame above it. Below, you will find how both parts work together to control movement through the mine shaft and keep lifting operations safe.

The winding drum stays inside the winding house

It is where the movement begins. When that drum turns, it either pulls the cage up or lets it down. Everything starts from here.

The cable connects both systems

It runs straight from the drum, goes up and over the sheave wheels sitting on top of the head frame, then drops down the shaft. That’s the path.

The head frame supports the pulleys

Those pulleys (or wheels) are fixed above the shaft. The cable goes over them, and that’s what changes its direction — from horizontal in the drum to vertical down the mine.

Both parts work as one.

If you only have the winding house but no head frame, the cage cannot be guided. And if you have a head frame but no drum turning inside the hoist room, then nothing moves.

What happens in the winding house of a mine directly affects how smoothly the head frame operates above the shaft.

To learn how the sloped legs of the head frame support this system, see Why Do the Legs on a Head Frame Always Slope Toward the Winch?

Safety and Technology in Modern Winding Houses

Modern mines look very different from the old ones, especially when it comes to safety and control. In today’s setup, what happens in the winding house of a mine involves advanced sensors, automatic brakes, and computer systems that make lifting safer and more precise. Below, you’ll find how these modern upgrades keep both miners and machinery protected.

Old systems used manual signals, but newer ones are automatic

Today, winding houses in modern mines use control panels with sensors. Instead of waiting for the bell to ring, the winder sees digital alerts or screen prompts.

Emergency brakes are more advanced now

Mines in places like South Africa and Canada use computer-controlled safety systems. These brakes kick in fast if anything goes wrong — even before the winder reacts.

Depth tracking is digital, not mechanical

Older dials have been replaced with digital depth monitors. This helps reduce mistakes and makes sure the cage stops at exactly the right level every time.

While the winding house manages movement, the headgear above ensures the structure stays balanced and safe during every lift. With new systems in place, what happens in the winding house of a mine today is guided by sensors, automation, and strict safety checks. If you have ever wondered how the tall steel frame above the shaft keeps the hoist cable balanced, you can learn more in our detailed guide on what the head frame does in a mine.

Classroom View – Winding House Function (Grade 8 Explanation)

You might have seen an elevator in your school. That lift goes up and down because of a motor somewhere behind the scenes, right? A winding house is like that motor room, but for a mine. It is not a big place, but it controls how miners and equipment move underground.

There is a person, called a winder, who makes sure everything stops exactly where it should. It is an integral part of Grade 8 Technology because it demonstrates how machines help people work safely and efficiently.

Final Thoughts

The winding house keeps the mine running. It controls the cage, manages signals, and protects the people who work deep below the ground. Everything comes together here: the engineering, the timing, and the safety checks. Without it, the shaft cannot operate.

FAQs

What happens in the winding house of a mine?

You will find the winding house as a place where the hoist machine is kept. This machine moves a strong cable that pulls the cage up or down the mine shaft. A trained operator waits for signals from workers underground and then controls the lift using switches or levers.

Every time the cage moves, it starts from here. If this machine stops working, nothing in the shaft can move. That is why the winding house is so important for safety and daily operations.

What happens in the winding house of a mine grade 8 answers term 3?

In Grade 8 Term 3, learners are taught that the winding house is the building where the lifting system of the mine is controlled. It holds the machine that pulls the cage up and lowers it back down.

The winder follows signals to move the cage safely between levels. This setup is used to carry workers, tools, and rocks. The cage would not move inside the shaft without the winding house.

Discuss the five stages of the mining process.

- Exploration: Geologists locate mineral deposits using surveys, sampling, and mapping.

- Development: Detailed planning, feasibility studies, and construction of mine infrastructure.

- Extraction: Minerals are removed from the earth through surface or underground mining.

- Processing: Ores are crushed, milled, and refined to extract valuable minerals.

- Closure and Rehabilitation: The mine is closed, land restored, and environmental monitoring continues.

What is the last stage of a mine?

The last stage of a mine is the Closure and Rehabilitation stage.

It involves:

- Monitoring the site for environmental safety and long-term stability.

- Shutting down mining operations safely.

- Removing equipment and waste materials.

- Restoring the land to a stable, natural, or usable condition.

What does the headgear of a mine do in grade 8?

The headgear is that tall structure you see right above the shaft. It holds the pulleys up top, the ones that help guide the cable from the hoist. The cable runs over those pulleys. That is how the cage moves smoothly in the shaft. Without the headgear holding things steady, the cable would go off track, and the lift could swing or even come to a stop. That’s why the headgear matters in mining.

Tarun Asrani is the founder and editor-in-chief of SmartAfricaGuide. With extensive experience in digital publishing and content strategy, he leads the platform’s focus on finance, scholarships, e-learning, and career opportunities shaping Africa today. Tarun visits Africa twice a year, gaining first-hand exposure to local education systems, job markets, and emerging technologies. He also closely follows African news, university updates, and government initiatives to ensure SmartAfricaGuide delivers timely, accurate, and practical insights grounded in real regional experience.