Last updated on January 8, 2026

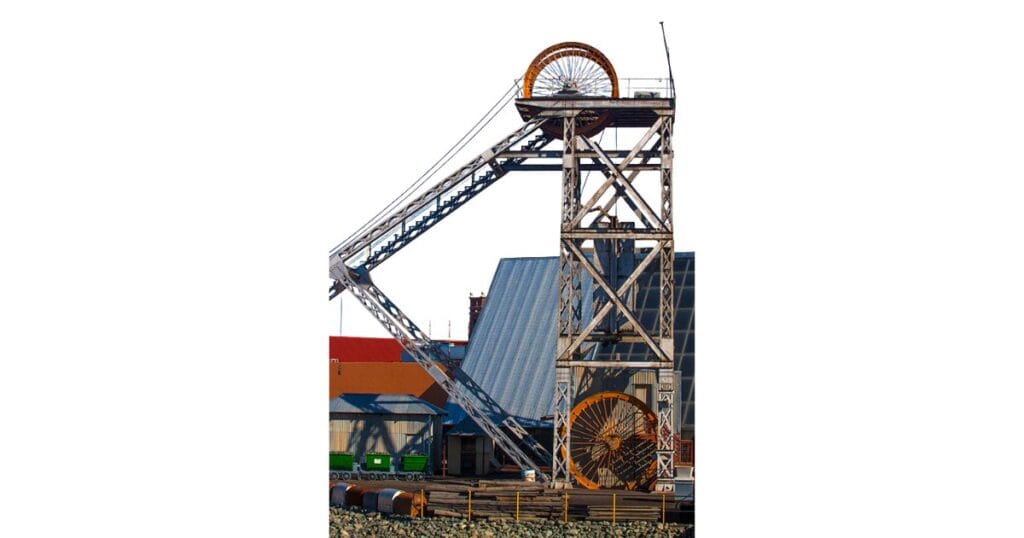

You have seen those tall metal structures standing over mine shafts, right? The kind that almost looks like a tower frame? That is the headgear. Now, if you have ever wondered what does the headgear of a mine do, it is mainly there to help pull things up and down. The headgear of a mine lifts people, rock, and equipment in and out of the shaft. It supports the hoisting system, keeps cables aligned, and makes underground transport safe and efficient.

Many people visiting a mining site often wonder, What does the headgear of a mine do, Since it stands tall above every shaft, yet works so quietly. Anyway, we will look into how this thing works, why it is built this way, and what it can actually teach you in class.

Table of Contents

What Is a Mine Headgear?

It is the big structure you will see built right over the main shaft of a mine. That’s what people call the headgear. It is not just a frame; it holds everything needed to lift people and material up and down.

So, things like pulleys, sheave wheels, and the main support beams all sit on it. Now, sometimes you will hear folks use terms such as headgear and head frame like they mean the same thing. But usually, headgear also includes the working parts, like the fittings and hoisting parts, not just the outer frame.

Understanding what does the headgear of a mine do becomes easier once you see how the pulleys on top guide the hoist cable during every lift.

Back in the day, most of these were made of wood. Timber was easy to find and quick to build with. But now, it is mostly steel or concrete, especially in deeper or more modern mines.

5 Things the Headgear of a Mine Does

What Does the Headgear of a Mine Do? The headgear does a lot more than just stand above the mine. Here is what it really handles:

#1. Holds the sheave wheels at the top

There are sheave wheels right at the top; those are the large pulleys the cable loops over. The headgear supports them and keeps them in place while the cable moves up and down. These wheels help guide the cable so it doesn’t drift or get caught.

That’s the core of what a head frame does, but when people ask what does the headgear of a mine do, they’re asking about the entire system — not just the frame.

#2. Lifts the cage and skips through the shaft

The cage carries people. The skip lifts rocks, ore, or waste. Both rely on cables that move through the headgear. It guides the entire lift system so that whatever’s inside the shaft gets moved safely to the surface or back down.

Many learners search “what does the headgear of a mine shaft do?” – this is it: safe lifting, up and down, every single day.

#3. Transfers the force from the winding drum

A winding drum spins inside a nearby building called the winding house. It pulls the cable with a lot of strength. The headgear takes that force and directs it downward using the shaft. The lift can tilt or shake if that force is not balanced.

#4. Keeps the cable in line and tight

Cables can be heavy, and if they are not kept straight, things go wrong fast. The headgear holds them steady, keeping the tension right and the path clean. No slack, no twist, just smooth, steady movement.

#5. Makes safety checks possible

There are usually walkways or ladders attached to parts of the headgear. Workers climb up to inspect the pulleys or tighten bolts. They don’t need to shut the system down — they just go up and check when needed. When learning what does the headgear of a mine do, it’s important to note that its strength and design are key to preventing accidents during hoisting.

Practical Example from South Africa

Mines in the Witwatersrand? Some go down over 3,000 meters — no joke. That’s a lot deeper than most folks imagine. The headgear there? It has got one job, but it is a big one. It has to lift several tonnes straight up, repeatedly. And it can’t mess up, not even a little.

If one pulley shifts or a bolt’s out of place, something could jam. It is that sensitive. That is what makes this setup so important. You ask what does the headgear of a mine do in South Africa, and yeah, this is it, it keeps the whole lift balanced under crazy pressure.

How Does the Headgear Work With the Winding House?

A clear diagram can help show what does the headgear of a mine do, especially how the pulleys and cables work together to lift the cage safely through the shaft.

These two systems – the headgear and winding house – need each other to move anything underground. Here is how the connection plays out:

The drum in the winding house spins the cable

Inside the winding house, there is a drum. It winds the hoist cable in and out. That’s where the pulling begins.

The cable goes through the top of the headgear

From the drum, the cable travels up and over the sheave wheels fixed on top of the headgear. Then it heads straight down the shaft.

The cage moves when the drum turns

The cable is linked to the cage. So when the drum turns, the cage either goes up or it drops. Depends on which way it’s spinning.

The operator controls the timing

There is someone in the winding house, watching everything. They manage the brakes, the signals, and when the lift should stop or go.

What does the headgear of a mine do becomes clearer when you see how it works with the winding house to lift cages safely up and down the shaft.

What Are the Main Parts of the Mine Headgear?

Each part of a mine’s headgear plays a specific role in keeping the lift system working smoothly. Here is what they include:

Sheave wheels

These are the big pulleys at the very top. They guide the hoist cable and help it move without too much friction.

Head frame or legs

These strong vertical beams carry the full weight of the lifting system. They hold everything up and in place.

Cross-bracing

These diagonal supports add strength to the structure. They help stop the headgear from shaking or twisting under load.

Crown wheel platform

This flat section at the top supports the sheave wheels. It keeps them level and steady.

Cables and guides

These make sure the cage moves straight through the shaft. They keep it from swinging or bumping against the sides.

Operator platform or walkway

This part lets workers climb up and check the system. It is purposely used for routine inspections and repairs.

Each and every part of the headgear works in tandem to make lifting in a mine both possible and safe.

To understand what does the headgear of a mine do, it helps to look closely at its main parts—strong beams, pulleys, and cables that support the hoist system.

Why Is the Headgear Designed With Triangular Supports?

Triangles add strength

Triangles in engineering are used to make structures strong. They spread out the weight evenly. This helps prevent bending or breaking when heavy loads are involved.

Diagonal bracing forms triangles

On a mine’s headgear, you will often see steel beams running diagonally. These connect with vertical and horizontal parts to form triangle shapes. This setup keeps the frame from swaying or shifting when the lift is in use.

A common design in stable structures

Think about the metal frames used in bridges or tall towers — they also use triangles. That same idea applies here.

Like the frame of a bridge or electricity pylon, triangles make the headgear stiff and stable under heavy load.

The same design principle explains why the legs of a head frame slope toward the winch.

Types of Headgear Used in Mines

Mines don’t all use the same kind of headgear. What they choose usually comes down to how deep the shaft goes and which building material is easiest to find nearby. Let us look at the main types.

| Type | Material Used | Common Use | Example |

| Timber Headgear | Wood | Older or small mines | Historical shafts |

| Steel Headgear | Steel beams | Big, deep shafts | Common in South Africa, Canada |

| Concrete Headgear | Reinforced concrete | Mines needing less vibration | Some sites in Europe, Australia |

Some miners used wood back in the day, mostly because it was there, easy to cut, and cheap. But as mines got deeper, steel made more sense. It’s strong and handles heavy lifting without bending.

Concrete showed up later on, mostly when stability really mattered and where you didn’t want too much shaking around the shaft.

The Role of Sheave Wheels and Cables

The sheave wheel sits right at the top of the headgear. It’s a large, round pulley that helps guide the hoist cable as it moves up and over the frame. Without it, the cable would rub or drag — and that would wear it out quickly.

One key role of the sheave wheel is reducing friction. It lets the cable roll smoothly while the winding drum below pulls or releases it. If the wheel isn’t lined up just right with the drum, the cable might twist or slide off path, which can lead to failure or damage during lifting.

The sheave also keeps the motion stable when the cage or skip moves up and down the shaft. Everything depends on clean, accurate alignment between wheel and drum.

In Grade 8 Technology, this is taught as part of the pulley system, showing how a small force can lift a large load.

How to Explain Headgear Function in a Short Answer (Classroom Format)

The headgear of a mine holds the pulleys that guide the hoist cables. These cables move the cage or skip up and down the shaft. It keeps the cables straight and under tension, allowing safe lifting of people, materials, and equipment in and out of the mine.

The answer to what does the headgear of a mine do lies in how it directs the hoist cable, keeping it aligned and balanced during every lift.

Classroom Tip

This kind of question shows up in school tests now and then. One teacher might ask, “What does the headgear do in a mine?” while another could say, “Explain its purpose.” The best answers just keep it simple — mention the pulleys, the cables, and how it helps lift things safely.

Modern Innovations in Mine Headgear Design

These days, headgear design is not just about strength. It now includes systems that think, sense, and even correct small issues on their own. Here’s what has changed:

Sensors and control systems

Some headgears now come with sensors that track things like how much tension is on the cable, or if anything starts shaking. These link to systems that can act fast if something is wrong.

Better materials

Instead of using plain steel, new versions use lighter metals that still hold up under pressure. They also hold up better in places where it’s damp or hot.

Digital monitoring

There’s software that keeps an eye on vibration and force levels. That helps teams fix problems before they get worse.

Steel and concrete together

Some setups now mix materials. Concrete at the base, steel for the frame. It gives the best of both — strength and a bit of give where needed.

Modern headgear systems now utilize the best of both worlds: engineering and technology. This goes to show how mines have undergone transformation and are slowly but gradually becoming astute and safe to use.

Concluding Thoughts

In simple terms, what does the headgear of a mine do is provide strength, stability, and safety—without it, no mining lift could function properly.

Headgear does more than hold things up. It lifts. It guides. It keeps the cable steady so the whole system doesn’t fall apart. If anything shifts — even slightly, the cage won’t move right. That is when safety becomes a problem.

It is not just about structure or machines. Headgear is where engineering meets safety. There’s physics in how it lifts. There’s planning in how it’s shaped. And the way it all works together? That’s design thinking in real use.

Students don’t always see this in textbooks. But when they learn how headgear works, it clicks. They see how simple systems do big jobs underground.

Studying mine headgear helps students see real-life applications of physics, engineering design, and problem-solving.

FAQs

What does the headgear of a mine do (Grade 8)?

It is the big frame you see above the mine shaft. That is the headgear. Its main job? Holding the pulleys that the cable runs over. That cable pulls a lift — called a cage — which carries miners or stuff up and down the shaft.

Without the headgear, the whole lifting setup wouldn’t work. In class, it’s part of the pulley system topic. You’ll see how the force from the winding drum moves through the cable, and the headgear keeps it all steady and in line.

What happens in the winding house of a mine?

Inside the winding house, there’s a large drum that pulls or releases the hoist cable. This cable runs through the headgear and down the shaft. When the drum turns, it either lifts the cage up or lowers it into the mine.

The operator in the winding house uses controls and signals to manage the speed, braking, and timing. Every movement of the lift depends on how this drum works. It is the core of the entire hoisting operation in deep mining systems.

What is a sheave wheel, and what does it do (Grade 8)?

A sheave wheel is a large pulley found at the top of the mine’s headgear. Its job is to guide the hoist cable smoothly as it moves during lifting or lowering. Instead of letting the cable drag or rub against the metal frame, the sheave lets it roll with less friction.

This protects the cable and helps it move evenly. In Grade 8 lessons, it is often shown in pulley diagrams where a smaller force can move something heavy by changing direction through the wheel.

What are two important aspects of headgear?

One reason headgear is important is that it holds the pulleys that help lift things in and out of the shaft. Without that support at the top, the whole cable system would not work. Another reason is alignment.

The headgear keeps the cable straight so the cage or skip moves properly. If the cable twists or shakes too much, it could get stuck or cause problems during lifting. So, it helps with both support and safety in mining.

Tarun Asrani is the founder and editor-in-chief of SmartAfricaGuide. With extensive experience in digital publishing and content strategy, he leads the platform’s focus on finance, scholarships, e-learning, and career opportunities shaping Africa today. Tarun visits Africa twice a year, gaining first-hand exposure to local education systems, job markets, and emerging technologies. He also closely follows African news, university updates, and government initiatives to ensure SmartAfricaGuide delivers timely, accurate, and practical insights grounded in real regional experience.