Last updated on January 8, 2026

The legs on a mine head frame slope toward the winch so the weight of the cables, cage, and load is carried safely back into the ground. This angle directs the pulling forces into the supports instead of letting the structure tip or bend.

When the hoist lifts heavy rock or people, enormous tension runs through the winding rope. If the legs stood straight, the frame would face greater sideways stress and become weaker over time. By sloping the legs, engineers keep the pulley aligned with the winch, reduce vibration, and spread the load evenly across the base. The result is a stronger, more stable head frame that lasts longer and keeps hoisting operations safer underground.

Table of Contents

Understanding the Role of the Headframe

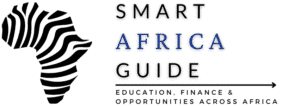

Above almost every mine stands a tall structure that catches the eye first — the headframe. It’s the landmark of any mining site, and here we take a closer look at what it does and why it continues to define South Africa’s mining skyline. When studying its form, engineers often revisit the core idea behind its geometry — why do the legs on a head frame always slope toward the winch, and how does that affect the rope forces acting on it?

What Is a Head Frame?

A headframe, often called a headgear or even a winding tower by mine workers, stands right above the main shaft of a mine. It holds the large pulley wheels that guide the steel ropes from the winder inside the engine house down into the deep working levels below.

The frame supports all vertical loads from the skip or cage and transmits them safely into the foundations.

According to the ISO standard ISO 19426-2:2018 – Structures for Mine Shafts, Part 2: Headframe Structures, headframes must be designed to resist vertical, horizontal, wind, and dynamic hoisting loads.

In South Africa, both steel lattice and reinforced-concrete headgears are common—the latter is favored in the deep gold mines of Gauteng for its rigidity and fire resistance.

What Is the Purpose of a Head Frame in a Mine?

The headframe performs four primary functions:

- Hoisting Support – holds the sheaves that redirect the rope from the winding drum to the cage or skip.

- Guidance – keeps the conveyances aligned in the shaft via guide ropes.

- Structural Transfer – transmits hoisting loads to the ground.

- Safety & Access – provides mounting for headgear sheaves, emergency braking, and service platforms.

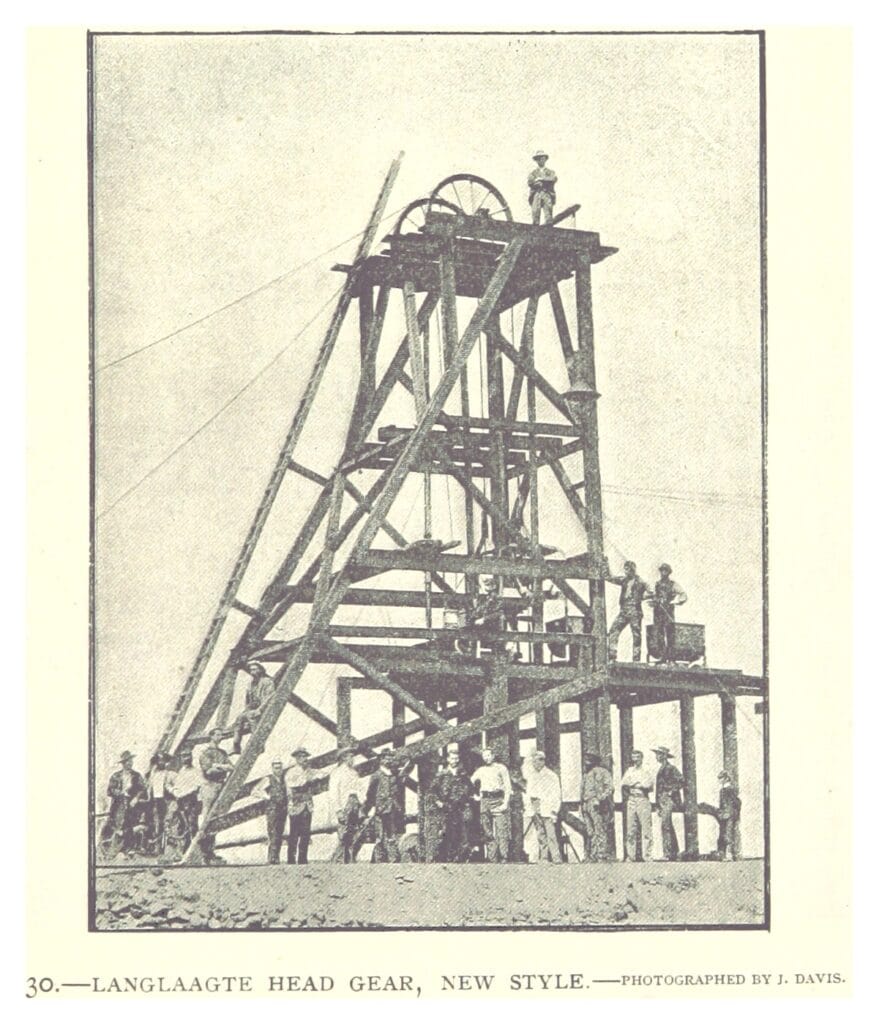

As The Heritage Portal notes, the earliest headgears on the Witwatersrand were simple timber A-frames; today’s versions reach 70 m or more, carrying steel sheaves weighing several tonnes. Their apparent lean is part of an optimized structural geometry, not an aesthetic choice.

The same concepts are taught through technical learning platforms for engineers, helping students visualize how geometry, force, and material strength work together inside a headframe.

What Happens Inside the Mine’s Winding House

The winding house, often marked as “A” in school diagrams, holds the winder — a huge drum powered by a strong motor. This machine controls the steel rope, lifting and lowering the cages or skips that travel through the mine shaft.

In many South African mines, the winder runs on electricity and has its own built-in brake and safety setup. One turn of the drum lifts a cage while the next lowers another, keeping the movement steady on both sides.

After leaving the winder, the steel rope climbs upward and then bends out toward the big sheave wheel fixed on top of the headframe. That bend adds a sideways pull toward the winder and a downward tug from the heavy load. The slight slope of the headframe is what keeps those forces balanced instead of fighting each other. This balance is the same reason why the legs on a head frame always slope toward the winch, forming one continuous line of tension from drum to foundation.

What Do You Call the Two Parts of the Lift That Go Down a Mine?

The mine’s “lift” system has two main conveyances:

- The Cage – carries miners and materials.

- The Skip – carries broken ore or coal to the surface.

These move in opposite directions on the same rope system for counterbalance. South African mining colleges and TVET syllabuses (e.g., Department of Mineral Resources & Energy Training Modules) refer to them collectively as the hoisting conveyances. The headframe and winch together coordinate their movement.

The Mechanics Behind the Slope

The lean of a headframe is no design accident. It’s deliberate — a reflection of why the legs on a head frame always slope toward the winch and not away from it. Here you’ll see how ropes, pulleys, and forces all combine to make that forward slope essential rather than decorative.

Understanding the Sheave Wheel — The Pulley at the Top

A sheave wheel is the large pulley mounted at the crown of the headframe. Its purpose is to redirect the rope from the horizontal winch drum down the vertical shaft.

According to Britannica, a sheave reduces friction and changes the direction of force, allowing heavy loads to be raised efficiently. In a mine, each rope passes over its own sheave. The deep-level shafts may have up to six. The sheave’s bearings and grooves are precision-machined to manage rope speeds exceeding 15 m/s.

How the Headframe and Winch Work

- Inside any mine, the winder, rope, and top wheels of the headframe move in step, each part depending on the next.

- As the drum turns, the rope lifts one cage while the other slides down, both moving with the same steady pull through the shaft.

- The small rope deviation angle (usually between 10° and 18°) decides how much the headframe must lean to stay balanced.

- In South African mines, double-drum winders are common — one rope lifts while the other lowers, keeping the load even. This setup, as explained in the Mine Hoisting Systems guide, defines the rope deviation angle that controls how much the headframe leans toward the winch.

- Each rope pulls both upward and sideways, so the headframe legs slope toward the winch to absorb the combined force safely.

- The winder house and headframe stay perfectly aligned on one axis to prevent uneven tension, rope wear, or drum vibration.

- This setup keeps high-speed hoisting smooth and reliable in deep gold mines across Gauteng and other mining regions.

Why the Legs on a Head Frame Always Slope Toward the Winch

This is the heart of the design and the main question driving this article. To understand why the legs on a head frame always slope toward the winch, one must see how rope tension creates both vertical and sideways pulls that meet at the sheave axle.

When the rope exits the winder, it pulls the sheave wheel toward the winding house while the cage weight pulls downward. The resultant force on the sheave axle has both a vertical and a horizontal component.

If the headframe’s legs were vertical, that horizontal component would cause bending moments at the leg bases and could tilt the whole frame.

By sloping the legs toward the winch, engineers align the structural members with the resultant force vector. The tension in the rope passes axially through the legs into the foundations, minimizing bending.

Research confirms that angled headframes experience lower stress and reduced steel weight for the same hoisting capacity.

Engineering Breakdown: How Forces Act on a Sloped Headframe

| Force | Vertical Component | Horizontal Component |

| Source | Weight of skip/cage | Rope pull toward the winch |

| Structural Response | Axial compression in the legs | Lateral bending moment |

| Solution | Sloped legs carry both in compression | Aligns the resultant through the leg axis |

This alignment allows a lighter, cheaper, and more stable structure—critical in South African deep-level mines where headframes must support over 5,000 kN of load.

“When a rope pulls from the winder, geometry—not guesswork—keeps a 5000-kN structure standing tall.”

Why Do the Legs of the Shaft Tower Always Run Diagonally Toward the Winch?

The legs are set on a slant so the pull from the rope passes close to the middle of each support. That way, the force stays balanced through the frame instead of twisting it or making it bend.

In Gauteng’s deep shafts, such as Mponeng or Moab Khotsong, that small geometric correction translates into millions of rand in saved steel and maintenance.

Why do the Legs on the Headgears Look Toward the Part labeled A?

In South African Grade 8 textbooks, the winding house is labeled A. The headgear’s legs appear to “look toward A” because they literally lean in that direction to carry rope tension efficiently. It’s an intuitive way to help learners visualize mechanical force balance.

Structural Design and Material Choices

From old timber A-frames to modern steel towers, engineers have refined every bolt and beam of the headframe. This refinement also reinforces why the legs on a head frame always slope toward the winch, because that single adjustment distributes the heavy loads evenly into the foundations.

If you want to understand how subjects like engineering, technology, and community industries are introduced to students, you can read our explanation of what social studies means in school.

Do You Think I-Beams Are a Good Thing to Use for Head Frame Supports?

Structural engineers often use I-beam or “I-flange” steel shapes as supports, because these profiles provide high stiffness and strength. The shape resists bending and buckling, making it ideal for compression members under axial load.

When a headframe goes up, crews still reach for those heavy steel beams shaped like an I or an H. They’ve learned that shape keeps its line even when the wind shakes the tower or the ropes pull hard. In newer mines, lighter steel does the same job with less metal, which makes the lift easier and faster to build.

Down near the coast in KwaZulu-Natal, the salt in the air bites at bare steel, so before anything leaves the yard, workers give each piece a coat of zinc or dip it in hot zinc to keep the shine from turning brown.

Modern Design Trends — 3D Modeling, I-Beams, and Sustainability

Today’s South African headframes combine classical geometry with modern engineering.

Designers now employ 3D finite-element modeling (FEM) to test load paths digitally before construction. These simulations confirm the same principle: sloped legs aligned with the rope’s pull deliver lower stress concentrations than vertical configurations.

Sustainability goals are influencing design choices as well. Mines are replacing older heavy concrete towers with modular steel frames. These can be dismantled and recycled after mine closure—reducing both carbon footprint and rehabilitation costs.

Why Do the Legs on a Head Frame Always “Loop”?

Some older educational materials misprint slope as loop. The principle remains the same: the legs lean toward the winder to align forces and stabilize the tower. There is no actual loop; it’s an angular offset determined by rope deviation calculations.

Headframe Foundations and Stability in South African Mines

Each sloped leg of a headframe rests on a base built to take an enormous push from above. Beneath every leg lies a thick concrete block or a deep footing held down by steel bolts that run into firm soil or rock. This setup reinforces why the legs on a head frame always slope toward the winch, as the angled supports push the load straight through to the foundation instead of bending sideways.

When the supports are planned, engineers don’t only think about the hoist. They also watch for what the wind can do, how the ground might move, and the hard shake that runs through the frame when the cage comes to a stop.

In KwaZulu-Natal’s softer coalfield soils, engineers often use bored piles to anchor the foundations, while Gauteng’s hard dolomitic rock allows direct bearing pads. Western Cape quarry headframes, though smaller, follow the same principles—legs splayed toward the winch direction and bolted to heavy base plates.

Regular inspection of anchor bolts and grout levels is essential. Even a few millimeters of differential settlement can misalign the sheaves and cause rope tracking errors, so mines follow the South African Bureau of Standards (SABS) guideline for quarterly foundation surveys.

Operational Performance and Comparison

Once built, a headframe must perform efficiently day after day. The sections below compare how sloped and vertical designs behave and how that affects hoisting performance.

How Does Sloping Affect Winch Operation?

Proper leg sloping improves winch performance in several ways:

- Smooth Rope Entry: The rope leaves the drum and approaches the sheave at an optimum angle, reducing side wear.

- Even Spooling: Reduced lateral oscillation on the drum, improving rope life.

- Energy Efficiency: With low friction losses, there is lower power consumption.

- Safety Margin: Stable geometry reduces the risk of rope derailment or uneven tension.

These mechanical advantages once again illustrate why the legs on a head frame always slope toward the winch, a principle that’s guided mine design for generations.

These factors are documented in the SME Mining Engineering Handbook (section on Hoisting Systems) and in winder manuals used by mining contractors in South Africa’s platinum sector.

Comparing Vertical vs. Sloped Headframes

| Aspect | Vertical Legs | Sloped Legs (Toward Winch) |

| Bending Moment | High | Low |

| Material Weight | Heavy | Lower |

| Stability | Lower, requires bracing | Higher, self-bracing |

| Rope Alignment | Poor | Optimal |

| Typical in | Early 1900s timber headgears | Modern steel/concrete headframes |

Engineers use this data to demonstrate why the legs on a head frame always slope toward the winch, ensuring stability with minimal steel usage.

Real-World Examples in South Africa

You’ll see that same forward lean almost everywhere — in Gauteng’s deep gold shafts and in the coal pits of KwaZulu-Natal. The idea never changes. When the frame follows the pull of the rope, it stands firm, lasts longer, and takes the wind without fighting it.

- TauTona Mine, Gauteng – Steel headframe with prominent forward lean toward its winding house.

- Newcastle Coalfields, KwaZulu-Natal – Concrete headgears showing moderate slope; designed for shallower shafts, but the same principle.

- Kloof Gold Mine, West Rand – Multiple sloped-leg frames visible; angles determined by rope deviation of 12–15°.

- Palabora Copper Mine, Limpopo – One of the tallest concrete headgears in Africa, leg angle optimized for double-drum winder geometry.

Each example confirms that the slope is a deliberate structural choice, not architectural style. These real examples across the country clearly show why the legs on a head frame always slope toward the winch — to align mechanical forces perfectly between the winder and the shaft.

Why These Designs Matter for South Africa’s Mining Future

South Africa’s mining landscape is shifting toward automation, digital monitoring, and safety excellence.

Yet even as systems modernize, the headframe’s characteristic lean remains unchanged. That tilt is the product of more than a century of empirical refinement—from Kimberley’s first timber headgear to today’s towering steel structures in Gauteng.

The KwaZulu-Natal coal region, Gauteng’s gold belt, and the Western Cape’s mineral quarries all continue to rely on the same geometric principle that keeps hoisting safe and efficient.

Understanding why the legs slope toward the winch is not just academic—it is vital knowledge for mining engineers, TVET students, and safety inspectors who maintain Africa’s largest underground infrastructure network.

Summary: Structural Logic Meets Function

The reason the legs on a head frame always slope toward the winch is simple yet profound—alignment of forces. By leaning toward the winder, the headgear allows gravity and rope tension to flow smoothly through steel legs into the foundation.

This design:

- Reduces bending and fatigue.

- Improves safety and longevity.

- Optimizes material use—vital for South Africa’s cost-sensitive mining sector.

Across South Africa’s nine provinces, the same principle guides mine design—from Limpopo’s copper to Free State’s gold.

So, when you next look at a towering mine headgear, you’ll know why the legs on a head frame always slope toward the winch — it’s a design that marries strength, balance, and historical ingenuity.

FAQ

Why do the legs on a head frame always slope toward the winch?

The ropes don’t pull straight down — they also pull sideways toward the winding house. By leaning the frame in that same direction, the legs carry the weight in line with the pull. It keeps the tower steady and stops the steel from bending or straining at the joints.

Why do the legs on a head frame always loop?

It’s a spelling variation of slope—they lean toward the winch to align loads.

Why do the legs of the shaft tower always run diagonally towards the winch?

The diagonal directs rope tension into compression along the legs, preventing bending.

Why do the legs on the headgears look towards the part labeled A?

In textbook diagrams, A marks the winder. The legs face that way because the rope tension acts in that direction.

What does a head frame do in Grade 8?

It supports the sheave wheel, guides the hoisting rope, and enables the lift to carry miners and ore safely.

How does sloping affect winch operation?

Proper slope ensures a smooth rope path, reduced wear, and stable operation of the winding drum.

The logic behind sloped headframes also prepares learners for practical industry roles; those aiming to enter the field can start by mastering the basics of engineering careers in Kenya and beyond.

Tarun Asrani is the founder and editor-in-chief of SmartAfricaGuide. With extensive experience in digital publishing and content strategy, he leads the platform’s focus on finance, scholarships, e-learning, and career opportunities shaping Africa today. Tarun visits Africa twice a year, gaining first-hand exposure to local education systems, job markets, and emerging technologies. He also closely follows African news, university updates, and government initiatives to ensure SmartAfricaGuide delivers timely, accurate, and practical insights grounded in real regional experience.