Last updated on January 8, 2026

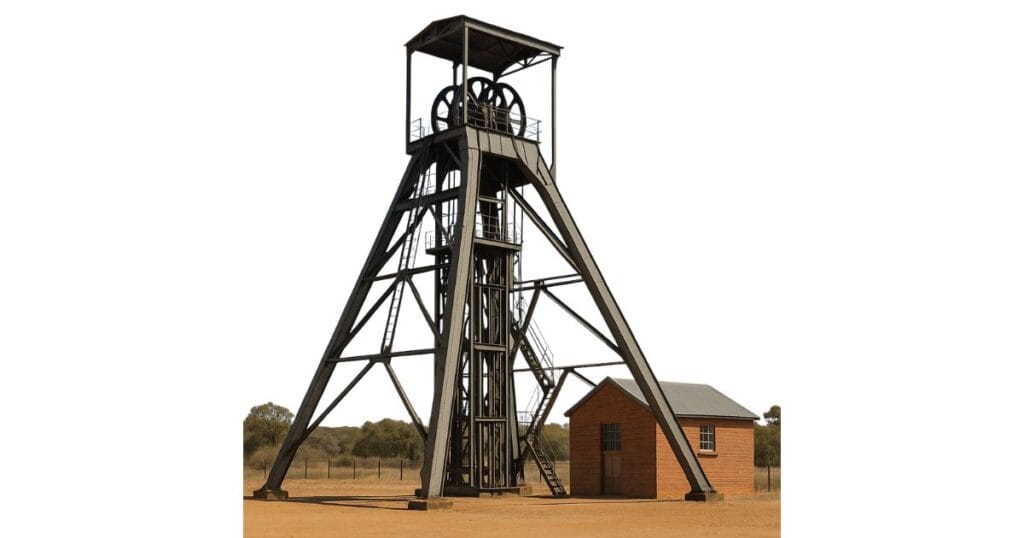

A head frame is the tall structure built above a mine shaft that helps lift workers, materials, and ore using ropes and pulleys. It’s a vital part of every underground mine.

In simple terms, it’s the backbone of every deep mine — balancing heavy forces, stabilizing ropes, and keeping hoisting operations safe and efficient.

You might have come across the question “What does a head frame do?” in school projects, especially in technology or Grade 8 lessons. But beyond textbooks, this structure represents an impressive mix of mechanical engineering and practical design — a blend of geometry, physics, and durability.

A head frame supports the hoisting system that raises and lowers people, equipment, and ore in and out of a mine shaft.

Quick Glance

- Supports the hoisting system above the mine shaft

- Carries loads from hoist ropes, sheaves, and conveyances

- Transfers dynamic and static loads safely to the foundation

- Guides vertical movement of cages and skips

- Ensures safe, controlled shaft operations under design limits

Table of Contents

What Does a Head Frame Do in Mining?

Walk into any old mine yard and you’ll notice the tall frame before anything else. It leans over the shaft like a guard keeping watch. It isn’t fancy or decorative; it’s simply the piece that ties the dark tunnels below to the loud clatter of engines above.

Up near the top sit a few heavy iron wheels, slow-turning things that the thick cables slide around while the hoist keeps working.

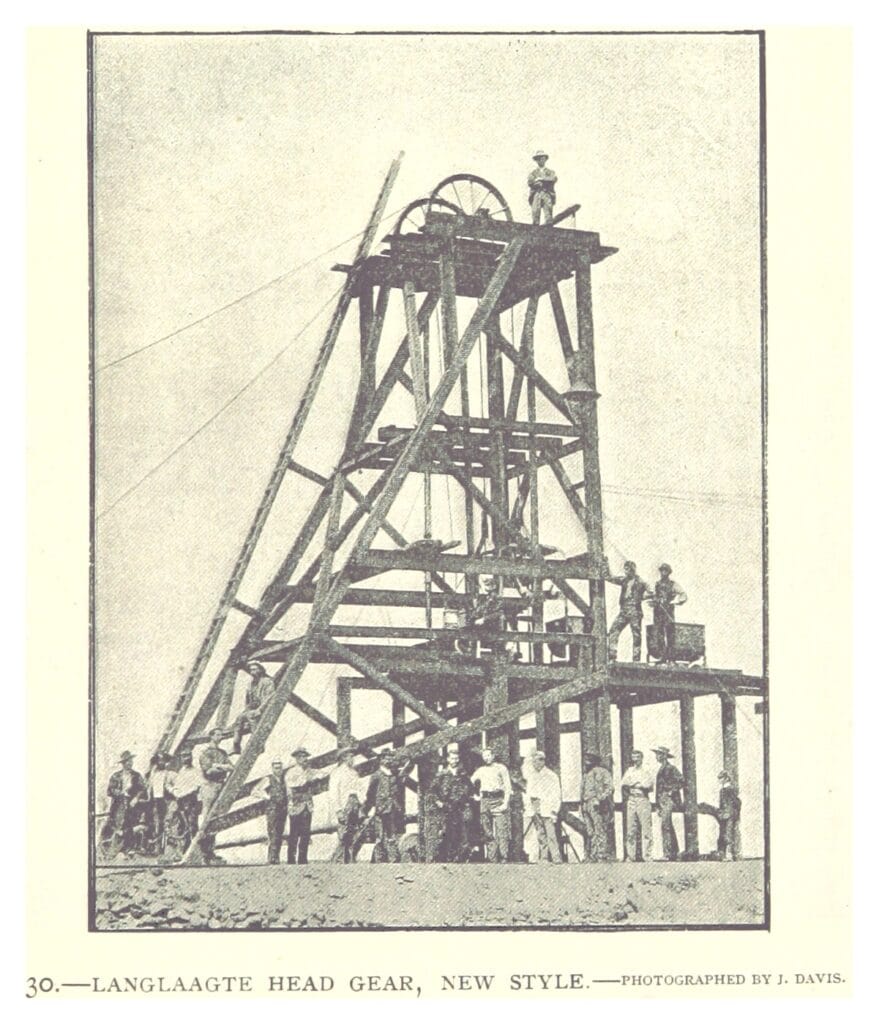

Old mines didn’t always look like this. Many began with rough timber frames—fast to build and cheap at the time. They worked for a while, but wood bends, cracks, and weakens when the loads keep growing.

“A head frame isn’t just a tower; it’s the link between life underground and the world above.”

As mining reached deeper seams, engineers switched to steel, and later on, to heavy concrete. That one change made an enormous difference. The lifts became steadier, accidents fewer, and the whole system felt safer for the crews who trusted it every single day.

The head frame must also provide enough height and clearance to allow skips to be raised completely out of the shaft before unloading. In some designs, ore is tipped into storage bins right beside the frame, while others use conveyors or chutes that carry material to processing areas.

Core Functions of a Head Frame

Here are the core functions of the head frame:

a. Supporting the Sheave Wheels

The sheave wheels at the top of the frame redirect the hoisting cable from horizontal (coming from the winder) to vertical (going into the shaft). This is where enormous tension acts, and the head frame’s job is to bear those loads and keep them perfectly aligned.

b. Transferring Load to the Ground

Every hoist movement creates a mix of compression and tension. The head frame absorbs these forces through its sloping legs and transfers them to its foundations. The better the load distribution, the longer the system’s lifespan.

To understand why these legs slope in a specific direction, read our detailed engineering explainer on why the legs on a head frame always slope toward the winch

c. Providing Rope Alignment

Cables running from the winding house travel toward the sheaves at an angle. The head frame keeps the rope’s path straight and smooth, ensuring that skips and cages move vertically without friction or side sway.

d. Offering Vertical Clearance

The upper section allows room for the cages or skips to be raised entirely out of the shaft. This prevents collision with the shaft collar and enables smooth dumping of ore into bins or hoppers.

e. Serving as a Safety Support

Head frames also anchor safety devices — braking systems, guide ropes, and over-travel limiters. Along the sides of the frame, narrow walkways and metal ladders let crews reach the sheaves for checks and greasing. The steps are dusty, the air often warm with oil, but every small inspection keeps the hoist running safely day after day.

How the Head Frame Works with the Winding House

A mine’s winding house — sometimes called a hoist house — contains the massive motor and drum that wind or unwind the cable. Power starts here.

Inside the winding house, the motor turns and the cable begins its climb toward the tall frame outside. It passes over the big pulley wheels on top before dropping straight down into the dark shaft with its load.

Nothing moves alone here — the power starts in the winder room, but the strength and balance come from the frame above. Both depend on each other, almost like two hands working the same job.

Materials and Design in Modern Head Frames

These days, most new head frames are made from steel or from solid concrete. The choice depends on how deep the shaft goes, how much weight it must carry, and of course, the budget.

Steel frames go up quicker and feel lighter on the foundation. They can flex a little when the wind or load shifts, which helps them last. The only catch is that steel needs care—paint, checks for rust, and a steady hand on maintenance.

Concrete versions are sturdier and almost maintenance-free, ideal for long-term mines or those in harsh climates.

The use of truss patterns — triangular sections — distributes forces evenly across the frame. Legs are deliberately sloped toward the winch to balance the pull of the hoist cable, ensuring that tension forces follow straight, predictable lines down to the foundations.

That careful balance between the slope of the legs and the weight they carry is what keeps a head frame standing firm, even when it’s lifting tons of rock in a rush.

The whole idea comes down to simple but clever thinking — using angles, weight, and common sense physics to make the structure steady without wasting material.

Head Frame vs. Headgear: Are They the Same?

In South African and British mining terms, “headgear” is simply another name for “head frame.” Both describe the same structure, though design styles can differ slightly between regions.

Headgear might include extra enclosures, covers, or pulley supports, but their role — lifting and guiding — remains identical.

The Head Frame’s Role in Safety and Efficiency

A good head frame does more than just hold up the ropes. It keeps the whole operation steady and the people working under it safe. When the ropes stay straight, the whole thing works better. The wheels at the top turn easy, not fighting against the pull. You can hear the motor hum instead of strain. The cables last longer, and the crew doesn’t have to stop as often to fix small things.

Before a new frame ever stands over a shaft, engineers spend days testing. They shake the model, push it with wind in a simulator, and watch how it bends when the load changes. It’s slow work but worth the time. To someone passing by, the frame might look like nothing more than a tall metal tower, yet to the team that built it, every beam and bolt carries the memory of those quiet checks that make the mine safer.

Topics like mining, machinery and community industries are sometimes introduced in school through Social Studies lessons. You can read our full guide on What Is Social Studies? to see how subjects connect to real-world activities.

Learning Application: What Does a Head Frame Do in Grade 8 Technology?

For students learning about mining technology, the head frame is a great example of how mechanical advantage and structural design come together.

In Grade 8 technology projects, learners often build small-scale head frames using cardboard, string, and pulleys to demonstrate lifting systems. The idea is to visualize how the real structure multiplies effort — using pulleys to lift heavy loads with less force while keeping everything stable.

So, when you see the question “what does a head frame do in Grade 8?” or “explain what does a head frame do”, remember: it’s a real-world application of physics and engineering — not just a diagram in a textbook.

Real-World Examples

Head frames can be seen across major mining regions in Africa and beyond.

The Kimberley Mine headgear in South Africa and the Langlaagte Gold Mine are iconic structures showing how design evolved from timber to steel.

Each represents decades of mining heritage and innovation, where form follows function — every beam and angle has a reason.

FAQ

Q1. What does a head frame do in a mine?

It supports and guides the hoisting system that lifts ore and miners between the surface and underground levels.

Q2. What does a head frame do in mining?

It anchors pulleys, aligns hoist cables, and provides the vertical structure needed for safe lifting.

Q3. What does a head frame of a mine do?

It redirects hoisting ropes from the winding house to the shaft and bears the entire load of mining conveyances.

Q4. What does a head frame do in technology or for Grade 8 students?

It demonstrates how structures and pulleys combine to move heavy loads using balanced forces.

Q5. Explain what does a head frame do (answers for Grade 8).

A head frame helps lift loads from underground using cables and pulleys. It keeps the rope straight and transfers weight to the ground safely.

Recommended Reading

If you want to explore the engineering behind the sloped-leg design, read our main pillar article: Why Do the Legs on a Head Frame Always Slope Toward the Winch?

Final Word

A head frame isn’t just an industrial structure; it’s the result of precise engineering logic that makes modern mining possible. Whether you study it in a Grade 8 classroom or encounter it on a working site, its purpose remains the same — to lift, guide, and stabilize every movement between the deep earth and the daylight above.

Tarun Asrani is the founder and editor-in-chief of SmartAfricaGuide. With extensive experience in digital publishing and content strategy, he leads the platform’s focus on finance, scholarships, e-learning, and career opportunities shaping Africa today. Tarun visits Africa twice a year, gaining first-hand exposure to local education systems, job markets, and emerging technologies. He also closely follows African news, university updates, and government initiatives to ensure SmartAfricaGuide delivers timely, accurate, and practical insights grounded in real regional experience.